Assalamualaikum and have a nice day everyone, today we are given the new task for chapter 6. This group discussion consist of 3 members, I, Nur Hidayah Binti Zarapi, Nur Syafiqa Binti Ibrahim & Puteri Shazmira Sofea Binti Safie and we are from the Solenoid's group.

As we know that Risk is a combination of likelihood and the probability that a particular occurrence or outcome and the severity of the harm(injury or damage)

As we know that Risk is a combination of likelihood and the probability that a particular occurrence or outcome and the severity of the harm(injury or damage)

WHY WE NEED RISK CONTROL ?

This is because we need to reduce risk

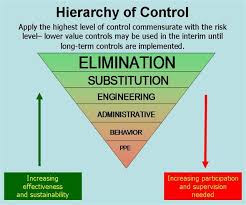

CLASSIFY HIERARCHY

1. Elimination Action

Elimination action is remove the hazard from the workplace . For example , Get rid of the dangerous machine

2. Substitution Action

Substitution action is replace

with less hazardous condition , practice of process . For example ,

Replace the machine with the safer one .

|

3. Isolation Action

Isolation action is remove people from hazard . For example , Fixed guard

4. Enginneering Control Action

Enginneering control action isolate people from hazard . For example , Attach guards to the machine to protect users .

5. Adriministrative Control Action

Adriministrative control action is

change the way people work . For example , Traine worker how to use the

machine safety or instruction sign .

6. Personal Protection Equipment (PPE) Action

PPE action is protect worker with

personal protection equipment which is wear something protection to

protect body . For example , Wear gloves and goggle when handling the

machine .

WHAT WILL HAPPEN IF THE RISK IS NOT IN CONTROL?

Workers may got the serious accident that can cause them get into the hospital such as arm and leg broken, head blooded, and the most critical is death. In order to reduce the hazard or most critical hazard rate, the employer should show commitment towards safety and health practices & therefore giveful priority to promote enforce the safety & health rules in workplace. Hierarchy of control were use in order to minimize & control the most critical hazard that exist at the workplace. Next, to ensure the safety culture can be implemented in on organization. The management & workers have to take part in any safety & health programme and give a full cooperation when come to safety & health issues.We should practice safe and healthy of living in this world with applying the enforcement rules and regulation that related the workplace safety and hygiene. The most important things in this world is "health" without it life is nothing. What- If hazard analysis is a relatively simple and flexible method and identifying and analyzing hazard in a process, activity or system. It can be apply to a wide range of circumstances in almost all industries. As one of the process hazard analysis methods listed in the OSHA Process Safety Management standard, the What -If method has become a commonly use technique, both in regulated and non regulated operation

Reference :

1) https://thumbs.dreamstime.com/z/hirarc-26866997.jpg

2)https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEiCCE2g14EKuH2HWc9rjnhIMbFQydC0NbaM_T5Pv95DzKCB6Otf2De9_vKBMeIpUJpZMnDLh4xQLAf0ncxs7Ek05HaIZiZ99J8g-NZWAtwL-Mtav-p7mHtSsQz0uV5-7f0koqNFWNmcBsE/s1600/untitled+SHO11.JPG

3) Https://www.masma.com.my/single-post/2016/12/04HIRARCguideline/dosh

4) www.asec.com.my/hazard-identification-risk-assesment-risk-control-hirarc/

5)comp.utm.my.lab?p=2079

THANK YOU!

|

No comments:

Post a Comment